Daihatsu is launching an automobile model that will let buyers order 3D-printed "skins" to customize parts of the body. It's the next step in industrial additive printing.

10 Programming Languages And Tools Data Scientists Use Now

10 Programming Languages And Tools Data Scientists Use Now (Click image for larger view and slideshow.)

Automobiles have come a long way since the time when you could have yours in any color, as long as it was black. Paint color has long been a way to customize a car, but paint color alone is so very 20th century.

Car buyers want more choices in personalized transportation, and Japanese automaker Daihatsu -- which operates as a member of the Toyota Group -- is launching a project to give it to them. The company's Copen roadster will offer from-the-factory customization at a level previously unavailable in a mass market car, all courtesy of 3D printing.

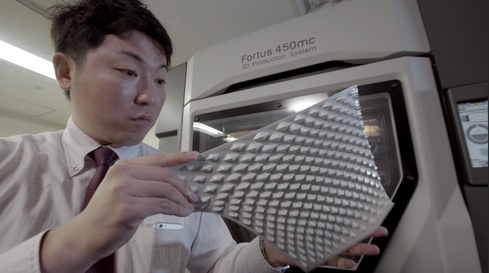

For the Daihatsu Copen, designers have developed a library of 15 different textured components they call "skins." These skins fit within the body shell on the nose and rear end of the car, and allow buyers to customize their auto in ways that previously required aftermarket parts.

In normal auto manufacturing, Daihatsu would create molds, jigs, and fixtures for the parts so these could be molded, cast, stamped, or machined (depending on material) by the hundreds and stored near the assembly line.

The parts would then be assembled onto each car in quantities determined by marketing research and sent to dealers in allotments. If a customer wanted a combination not available on the local dealer's lot, the customer could go to a different dealer, or the local dealer would find the proper combination at another dealer's location, and then arrange a swap to get the right car to the customer.

(Image: Stratasys)

With the Copen, buyers will go to the dealer and pick out the skins they want. The order will be sent to the factory where the necessary parts will be 3D-printed using Stratasys Fortus additive printers. According to a Daihatsu promotional video (seen below) a customer-designed car that might have taken two to three months to deliver under old production methods will be delivered in two weeks with the 3D-printed parts.

[How to get your kids excited about coding. Read 9 Tools for Teaching Kids to Code.]

In a telephone interview with InformationWeek, Jim Vurpillat, marketing program director automotive for Stratasys, said the ASA plastic used in the printed skins is a good match for the application. The skins are entirely external and not part of any structural or safety-cage system. The primary considerations are whether the skins' color will fade with time, and their ability to withstand the bumps and scrapes of normal automotive use.

Vurpillat said the plastic used will not fade. It can withstand normal wear and tear in the positions where the parts are attached. The material is lightweight -- a substantial plus at a time when auto manufacturers are trying to increase fuel economy ratings.

(Image: Stratasys)

Asked about the decision to locate the 3D printers at the assembly line, rather than in the dealer showroom, Vurpillat said that the cost and complexity of the printers being used made them more suitable for a central, highly controlled deployment.

He said the same process of printing on demand would be used for parts damaged in collisions or purchased for appearance updates. Daihatsu will not need to make and store parts for quick shipment to dealers and repair shops. New skins will be printed on-demand when ordered.

Vurpillat was unwilling to speculate about precisely how 3D printing will grow in the automotive industry, but he did say that Daihatsu's parent company, Toyota, is watching the Copen experiment carefully. As more and more body panels on autos are made of plastic, the opportunity for customization will only increase, since replacing and modifying parts doesn't require advanced metal-forming skills.

The Daihatsu Copen will be available in Japan starting later this year. Daihatsu has not announced plans for further expansion.

About the Author(s)

You May Also Like