Things To Do At Memphis International At 1 a.m. In December

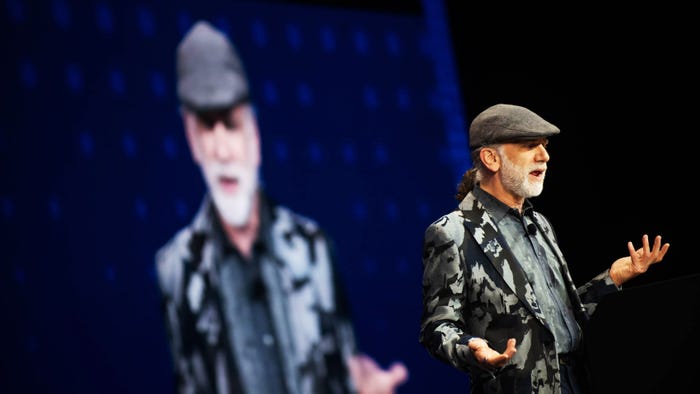

<i>InformationWeek</i> editor Rusty Weston and photographer Ken Schles watching "The Sort," when FedEx's air armadas disgorge millions of packages.

It's midnight on the chilly tarmac at Memphis International Airport and logistics class is now in session. You walk away chilled to the bone, but you can learn more about logistics here in two hours than in a dozen grad-school lectures. One hundred and forty planes are nosing into FedEx's national hub to off-load hundreds of tons of cargo, everything from Christmas gift baskets to legal briefs to auto parts. FedEx workers dart out to greet the planes, offload 3 million packages and then rush them into giant modified hangers to be organized by area codes in a frenzied exercise called The Sort.

When a customer's package leaves New York en route to Miami, it stops here first at what is the largest of six domestic hubs. Big or small, the package must get to the plane headed to Dade County, Florida, and not the one bound to, say, Oxford, Ohio. Minutes are crucial. To hit the morning package-delivery deadlines, the planes must be reloaded and heading skyward at 2 a.m. Alas, it takes three times longer to load a plane than to clear one out.

In roughly three hours, nearly 14,000 FedEx workers will execute a feat of choreographed commerce that makes synchronized swimming look like the Keystone Cops. Fortunately, we brought along a photographer, Ken Schles, to record this blazing nocturnal activity. In the next several hours he will snap hundreds of candid shots on a tour of this 400-acre facility.

To truly appreciate logistics, you have to see it, touch it, and try it. Even senior corporate execs pitch in during the holiday Sort. But our first lesson seems more like a fraternity hazing than a serious look at shipping. We stand in a field at the top of a runway as plane after plane descends--landing gear engaged--right above our heads. It occurs to us that there are people who would pay to have this harrowing experience.

Back inside the sorting facilities we encounter a conveyor belt at least 20 feet wide carrying a motley assortment of packages past an electronic sensor that reads the labels shortly before they spill off into tributaries that flow into hundreds if not thousands of bins. Later, we see the control room where a platoon of operations experts monitor the flow of planes and packages via closed-circuit TVs. The employees are looking for jams much the way transportation officials monitor urban highways. Here and there a package falls off the production line, and employees quickly jump out and intervene.

Later that morning, we learn that the hub came within minutes of meeting its deadline. But close isn't good enough. FedEx's operations experts will dissect the performance to figure out how to make things run smoother. Their customers wouldn't have it any other way.

|

|

|

|

|

|

|

|

|

Photos by Ken Schles

Return to main story, Time To Deliver

About the Author(s)

You May Also Like

How to Amplify DevOps with DevSecOps

May 22, 2024Generative AI: Use Cases and Risks in 2024

May 29, 2024Smart Service Management

June 4, 2024